Coated PET Film / Coated Polyester Film

Filmquest is a leading supplier and converter of coated polyester (PET) film.

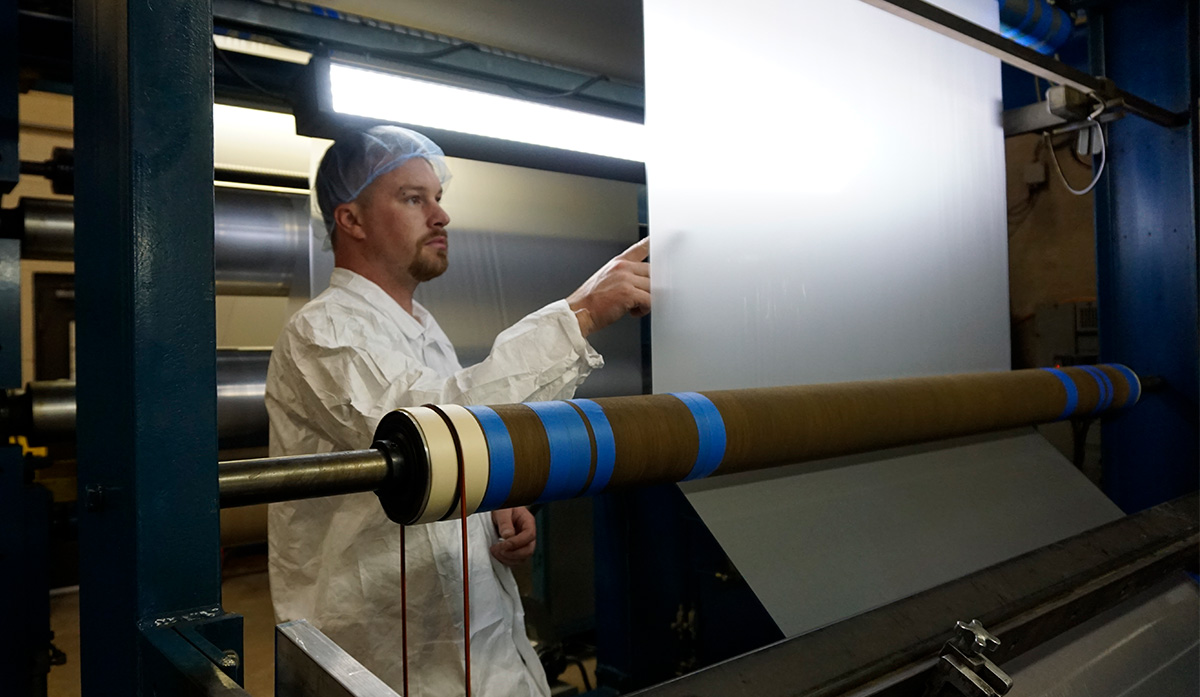

Filmquest coats all grades of PET film, supplying coated PET film in coated master rolls and slit-to-width rolls. Filmquest’s coating capacity makes for short lead times with competitive pricing.

The coating of the PET film adds an aesthetic that is useful for many applications, particularly when used for flexible packaging. It also changes other characteristics of the PET film, making it useful for many applications.

Questar® brand coated PET films represent a wide range of functional, tactile and visually appealing coatings including our Questar® brand Soft Touch PET film.

- Questar® brand soft touch coating

- Matte coating

- Tactile coating

- Color coatings

- NanoShield® brand high barrier coating

- Off coater or converted to custom roll specifications (same as PET offerings)

What is Coated PET Film?

Coated polyester film, also called coated PET film, is a plastic film that has been coated with a material on one or two sides of the film. The type and amount of coating applied determines the physical, mechanical, optical, thermal, electrical and chemical properties. Coated films may also be a combination of coatings and treatments, such as coated one side / treated other side depending on end-use application requirements.

Coated PET Film Technical Information

Coated PET film from Filmquest has various technical properties that make it a good choice for many applications.

Coated film offerings from Filmquest include:

- Corona treated PET film

- Chemically treated PET film

- Anti-static coated PET film

- Polyvinylidene chloride (PVdC) coated PET film

- Rolls coated up to 65” on coater

- Coated stock for coated slit-to-width roll offering

Why Choose Filmquest for Coated PET Film?

Customers choose Filmquest for coated polyester film because of:

- Complete range of Questar® polyester film grades

- Custom fabricated components

- Complete slitting

- Simple order entry via telephone, fax or email

- Rolls: any width, any configuration with precision slitting

- Clean room environment

- Competitive prices

- Fast lead times